Electrical Consultants & Energy Auditors

Energy Audit & Conservation Services

Upendra Deuskar and Associates : Energy Audit & Conservation Services

Energy Audit & Conservation Services

Methodologies we follow

Current harmonics are characteristics of load and are result of using non linear loads like rectifiers, UPS systems, AC/DC variable speed drives, arc/Induction furnaces etc. Non linear load current comprises of fundamental frequency current and currents of higher harmonic frequencies namely 3rd,5th,7th,11th and 13th harmonic etc. These higher harmonic currents result into overheating of electrical distribution system due to increased iron and copper loss requiring system derating on part of utility company and user’s electrical infrastructure. Excessive current harmonics can cause resonance and also introduce voltage harmonics. This is the reason utility company (Like MSEDCL) has put restrictions on current harmonics demanded by consumer through “Supply code 2005” and asks consumer to adhere to provisions of IEEE 519 1992.

Current harmonics can also cause internal problems within plant. Nature of such problems includes nuisance tripping of circuit breakers, abrupt breakdowns of electronic cards, loss of motor alignments, burning of motors etc. Reactive power compensation and harmonic mitigation cannot be isolated from each other as excessive compensation brings in amplification of current harmonics.

During harmonic audit we study historical data of electrical energy consumption in terms of monthly kwh and kvah from last 12 months electricity bills. Understand load trend over 24 hours load cycle and decide power quality monitoring periods based on our experience to collect worst case samples. While doing this we also understand single line diagram and note all nonlinear loads and their application in the process. Based on this knowledge various PCCs (Points of common contacts) are decided on SLD for monitoring of power quality parameters along with period of monitoring. Discussion with plant staff also is taken into consideration to address specific problems like capacitor / APFC contactor burnouts, cable overheating, machine maintenance problems etc.

A detail report is prepared based on all above information is prepared which includes

- Analysis of historical data to note lost incentives / paid penalties.

- Current harmonics compliance requirements as per IEEE 519 1992 and comparing recorded harmonics with the standard.

- Analysis of KVA demand and recommendations on demand optimization.

- Recommendations on reactive power compensation with harmonic mitigation within compliance limits. Filter design up to required detuning and KVAR steps. Required investment and paybacks.

- Recommendations on LT room / distributed compensation. Recommendations on HT / LT compensation as per need.

- Analysis of major non linear load feeders with harmonic levels recorded up to 50th order.

- Recorded data on each feeder arranged as individual and collective information along with comments, which can serve as a base line record for any further use.

- Behavior of captive / standby power generators while supplying harmonic loads.

- Any other information on power quality specifically requested by client.

We can also participate in implementing mitigation solutions through our experienced associates having backup of German technology. While executing recommended solutions, we take comprehensive responsibility of harmonic suppression and maintaining unity power factor for 2 years since installation.

These days Indian industry from all sectors is investing heavily in latest technology available worldwide. Sophisticated equipments and machines are installed in industries, which are expected to work reliably accepting available electrical power. Indian electric grids are not as stiff as they are in western world. (Grids can supply less as against demand at almost all time). Preventive and predictive maintenance of electrical systems do not get required importance in Industry. Earthing grids within plant are not well maintained. All this results into various power quality problems and associated equipment malfunctions and failures.

During power quality audits, we undertake almost entire scope as detailed in 1 above and in addition Infrared thermography is carried out for the entire electrical installation. This helps in finding out loose contacts in cable terminations etc during live working of the plant. Temperature profiles are recorded against actual measured currents. Capacities of installed power conditioning equipments like stabilizers, UPS systems etc are verified against their actual use. Output power quality is recorded while they supply to their respective loads. Plant earthing system is studied along with actual earth resistance measurements at point of use and earth pits. Neutral – Earth voltage is also monitored where ever possible.

Transient recording and Inrush current recording is also carried out where ever applicable and required. Power quality audits can also be conducted against compliance requirements of various applicable standards.

A report is presented based on above which will include:

- Power quality record as recorded at various feeders of interest, which will include voltage, frequency, voltage distortion, phase angles, V imbalance, Parameter trend over desired time period.

- Transient recording carried out if any.

- Current and voltage harmonics data.

- A detail report based on above data for abnormal/normal power quality parameters along with recommendations on mitigations at raw power and conditioned power level.

- Thermography report of all feeders along with specific recommendations on predictive maintenance.

Project design base data on electrical / Ventilation systems / Air conditioning systems / Air handling systems / Thermal systems etc is collected from client. We help client in refining these requirements if client is open for the same.

We undertake demand analysis based on this by applying basic engineering principals. and come out with actual equipment specifications with total responsibility of end results and optimized operating costs with enough safety. While doing so we use various CAD tools available with us and 30 years experience of our energy auditing team.

The preliminary designs prepared by various project consultants / contractors appointed by client are validated against these derived specifications. Various meetings are conducted with respective vendors to modify their designs to suit optimized requirements while ensuring delivery of client’s requirements.

Once designs are finalized, we monitor project execution as energy / third party auditors and at the end handover OPEX OPTIMIZED project to client.

We advice – help client in taking CAPEX decisions based on optimizing 5 years operating costs added to capital costs.

We also undertake ENERGY SIMULATION jobs and green building consultancy.

On request we undertake energy audits of various establishments. Comprehensive scope includes auditing all types of energies used by establishments. The activity studies effective and judicious use of energy. As detailed in above offerings, at every point of use, used energy is compared with ideal requirements calculated using basics of engineering. The discrepancies found if any are related to equipment performance and suggestions are offered for improving the efficiency. The exercise is done using various high end calibrated equipments to achieve maximum accuracy. The reports list out such modifications, their cost benefit analysis and payback periods.

The audits are of two types namely

- Walk-in audits

- Investment grade audits.

Walk-in audits revel Energy Saving Opportunities (ESOs) with budgetary cost/payback analysis, while Investment grade audits revel more precise proposals along with designs of proposed modifications. The entire exercise results into substantial saving of energy costs and effectively operating costs.

The Scope of Energy Audit

- Study historical energy consumption and electrical parameter data for preceding 12 months from electricity bills against occupancy.

- Undertake Electrical Power quality analysis and assessment of reactive power compensation available at present along with current harmonic analysis.

- Assessing ON LOAD efficiency of UPS systems.

- Division of total load into various utilities like Air conditioning / Illumination and IT by actual measurements and calculating percentage consumption by each utility.

- Validation of electrical switchgear and cable ratings with actual measured load.

- Study “on load thermal status” of all electrical equipments to check vulnerability to fire hazard using infrared camera.

- Demand analysis for air conditioning by actual site and occupancy measurements, calculating required capacity and predicting benchmark energy consumption for installed option.. Comparing them with present measured energy consumption for air conditioning and suggesting energy saving options with respective paybacks.

- Inspection of existing air conditioning units and measuring vital parameters to assess performance and quality of maintenance.

Energy Audit Methodology

- Once the work order is received, detail work schedule will be submitted to you date wise.

- We would require one person from your side to locate different equipments and to give us access to them.

- The whole audit work will not need any interruption in your working.

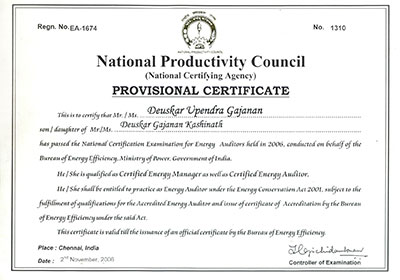

- BEE certified energy auditors (one from electrical side and one from mechanical side) will lead the audit.

- During audit, we will study all types of energy inputs – electricity, Diesel, for their judicious and effective use in the premises

- We will use high end equipments like recording type electrical power analyzer, IR thermometer / IR camera / Lux meter / Pressure Gauges / Air velocity meter etc for actual measurements.

- The audit process will take about one week, when auditors and measurement staff would visit your premises.

- Next one week will be spent in analyzing the collected data and information at our office. A detail report will be submitted to you along with our recommendations for safe and energy efficient working.

- The audit procedure may also include discussions with your equipment vendors to get required performance using optimum energy.

- We can also participate in implementing audit recommendations as a vendor where in our supervision charges will be included in our service charges / supply costs. Alternatively we can supervise implementation by other vendors selected by you on chargeable basis if needed.

Energy Audit Deliverables

We submit a report based on data collection, which includes

- Executive summary of audit findings.

- Summary of historical data / lost incentives / paid penalties etc on energy charges.

- Power consumption / parameter data of all electrical equipments on load and consolidation of the same. Validation of this total demand with your contract demand.

- Major cable size validation with actual current flowing through these cables.

- Power quality analysis for server rooms and work stations.

- Comments on power source redundancy available for critical feeders.

- Assessment of reactive power compensation and recommendations on harmonic current filtration based on actual on load recordings.

- Thermo graphic analysis of electrical system to check safety against fire and thermal stress on various electric equipments.

- Energy consumption by different utilities as measured and concerned Pie chart.

- Suggestions and recommendations based on above data for safe and energy efficient operation along with various paybacks for suggested investments.

- Demand side design validation of air conditioning systems. Report on physical inspection of existing AC systems and suggestions for their energy efficient operation and maintenance.

We are enclosing herewith details on our approach adopted during energy audit and other credentials for your reference.

Our Approach During Energy Audit

- Preliminary visit and subsequent quotation for walk in audit.

- Receiving work order for walk in audit.

- Conduct Walk in energy audit:

- Understand your process and equipments.

- A meeting with senior management to understand their requirements and commitments. Meeting with stakeholders to decide exact scope of energy audit.

- Submitting offer for actual energy audit.

- Receiving work order for energy audit.

- Detail documentation study of electrical system.

- Study of electrical energy bills for at least 6 months, preferable 12 months.

- Recording electrical parameters as per single line diagram involving main incomer and major feeders.

- Assessment of available electrical power quality including voltage, PF and harmonics profile

- Preparing report on facts and mitigation requirements as per prevailing rules and regulations so as to avail maximum incentives on electricity tariff.

- Detail study of other form of energy used by your establishment and associated processes to locate Energy Conservation Measures (ECMS).

Detail study of following (As decided by scope in the work order) to identify Energy Conservation Measures.

- Individual energy guzzling equipments

- Various processes

- Utilities like compressed air, water supply systems etc

- HVAC systems

- Illumination systems

- Present and proposed energy monitoring / management system.

Financial evaluation of suggested energy conservation measures:

- Classifying ECMs into No cost, Low cost, high cost categories.

- Calculating paybacks using various options.

Presentation of Audit report

- Discussions on audit findings with respective stake holders

- Preparation of executive summary of Audit report for higher management.

- Preparation of final report

- Presentation of executive summary

- Presentation of final audit report in soft and hard copy

- Follow up and implementation of suggestions at extra charges if required by client.

Our Happy Customers